The ring pack that came with my Mahle Racecast pistons is part #4075MDK-D, Steel DSL ringset. I know the OEM replacement rings for 01-10 are part number 41909 and have a ductile iron top ring , and the newer style rings part number 42160 and have a stainless steel top ring. I looked in the Mahle catalog and it doesn't state what material these new rings are made of. I read a few posts on here regarding the older rings not lasting as long and having gap issues. I'm not trying to go back into this motor once it's together for a while. Anyone who has run these pistons know what this ringset it made out of? I emailed Mahle last week and haven't received any info yet. Any help would be appreciated thanks.

Mahle Piston Rings.

- Thread starter Ironworker15

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Still no answer from Mahle. But on their Power pack piston brochure it says the forged pistons come with a PVD coated stainless rectangular top ring. Doesnt say for the cast. Anyone have an answer for me? Is it worth sending these back for the other rings?

I'm not sure on that. I will email the tech and get back to you. I'm sure one of the more experienced builders on here who have run these pistons would have the answer though. I do know cylinder wall finish has just as much to do with the rings seating properly and the longevity of them as the material the rings are made of so I would venture to guess Mahle must have some spec.

I have been looking but everything I found online is older information. I think the ring packs may have changed since then so I wanted to be sure.I'm not sure on that. I will email the tech and get back to you. I'm sure one of the more experienced builders on here who have run these pistons would have the answer though. I do know cylinder wall finish has just as much to do with the rings seating properly and the longevity of them as the material the rings are made of so I would venture to guess Mahle must have some spec.

So if they have a specific recomendation for these current ring packs I would like to pass it on to my machinist. They actually do a have a profilometer and can verify the surface finish is correct.

There was a few posts on here recommending stone grit and different Ra #s. But nothing specific to these pistons. I sent Mahle an email and will let ya know what I hear.

Cylinder wall honing surface finish & ring gap

What is the preferred surface finish for seating rings on Mahle's race cast pistons/rings? I have 240 and 320 grit hones available. Also what ring gaps are preferred (compression and second ring)? Running small twins and maybe a small nitrous jet to clean up as needed.

www.duramaxdiesels.com

www.duramaxdiesels.com

Yes, Thats the thread I found with Post #8 giving a finish spec. of

RPK of 12-18,

RK of 35-40

RVK of 50-60

with a 45 degree included angle.

My machinist found some other material That suggested a larger range and possibly higher numbers on the finish.

RPK of 10-20,

RK of 25-50 for high pressure/ forced induction 55-65

RVK of 30-60 for high pressure/ forced induction 65-75

There is actually more to honing with different types stones, not just grits, as well as Plateau Brushes that all effect the final finish.

I think the ring pack may have changed at least 1 or 2 times since the original post from 9 years ago. I would be curious to see what they currently recommend. I just haven't had time to call them.

RPK of 12-18,

RK of 35-40

RVK of 50-60

with a 45 degree included angle.

My machinist found some other material That suggested a larger range and possibly higher numbers on the finish.

RPK of 10-20,

RK of 25-50 for high pressure/ forced induction 55-65

RVK of 30-60 for high pressure/ forced induction 65-75

There is actually more to honing with different types stones, not just grits, as well as Plateau Brushes that all effect the final finish.

I think the ring pack may have changed at least 1 or 2 times since the original post from 9 years ago. I would be curious to see what they currently recommend. I just haven't had time to call them.

....and here I used a simple dingle ball hone on a drill, and the 41909 rings.....go figure....

Probably fine , if I wasn't over boring.020. If I was going stock replacements , I'd of done the same thing.

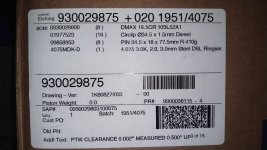

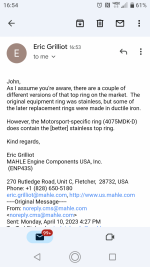

Wow, Thank you so Much!Ask and you shall receive. Here is the email I received from Mahle. Attached is the spec sheet as well.

No problem brother. That's what this forums about as far as I can tell. I've gotten a lot of good tech info on here so far. I'm sure each machinist/engine builder has their own personal preference when it comes to honing , but this seems to be a good starting point. Good luck with the build. Did you end up getting those Brian Crowers? I'm interested to see how they hold up myself. I did check all the pins and pin bosses on mine and no issues at all.

Attachments

I ended up with the Callies. They just came back in stock. Hoping they show up this week.No problem brother. That's what this forums about as far as I can tell. I've gotten a lot of good tech info on here so far. I'm sure each machinist/engine builder has their own personal preference when it comes to honing , but this seems to be a good starting point. Good luck with the build. Did you end up getting those Brian Crowers? I'm interested to see how they hold up myself. I did check all the pins and pin bosses on mine and no issues at all.

Nice. I've heard nothing but great things about them as well. A buddy of mine has them on his drag truck. Over 1000 to the wheels according to his 1/4 times and has had no problems so far. I almost went with them as well but they were out of stock everywhere when I was buying parts.

The BC rods do look nice. I don't plan to push mine nearly that hard. Mainly towing and some occasional fun...Nice. I've heard nothing but great things about them as well. A buddy of mine has them on his drag truck. Over 1000 to the wheels according to his 1/4 times and has had no problems so far. I almost went with them as well but they were out of stock everywhere when I was buying parts.

I am in the same boat, I couldn't afford to buy everything at once. I am slowly piecing it together. I think I have just about everything at this point.