2006 LBZ, 210,000 miles, EFI Live DSP 5, lift pump, still has everything else stock. I replaced the head gaskets over the last week, now I know why they want 5 grand in the shop, anyway, I fired it up and it runs rough and blows blue/white smoke, any ideas before I rip it all apart again. I did have to readjust the valves and set them at .0010, could it be a bad injector??

new head gaskets, now runs rough and smokes

- Thread starter IdahoMike

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I had coolant leaking btwn the lower valve cover and top of the head on the psngr side, it made no sense as I did not have coolant in the oil, I took it down to the lower valve cover and decided to replace the HG's seeing how I have over 200,000 on it and already torn down to this point. I bought the HG kit with the ARP blots. Before this it ran perfect except for the coolant leak. Of course I had to readjust the valves. The new injectors have maybe 10,000 on them, Bosch, thru Injectors Direct. I did not have the heads resurfaced, the old head gaskets looked brand new. Now I wish I never did this.

I've checked the # 2 and #7 they appear to be fine, no cracks or broken wires. I'm tearing it down again to recheck the valves, that is the only thing that was changed, I could be off 180, don't know till I have torn down. Fortunately I'm a little quicker at it now. It took me almost a week the first time, I have the psngr side exposed already and starting on the drivers side, maybe 8 hours total...Have you double checked all the electrical connections?

kinda doubt that, I already checked them, they are all clear plus they are relatively new Bosch injectors with maybe 10,000 miles on them. I can't see them going out that fast..Injectors are bad most likely. Get them from Lincoln diesel specialties

If you can get a video that might help us figure it out. Where about in Idaho are you? I am in the Treasure Valley and might be able to come look in person with my scan tools if you are in that general area.

I tend to agree that it is unlikely an injector went out, unless they were damaged/contaminated during the work. If you were careful and clean, that is probably not the problem. Having the valve lash way off could do what you are seeing.

I tend to agree that it is unlikely an injector went out, unless they were damaged/contaminated during the work. If you were careful and clean, that is probably not the problem. Having the valve lash way off could do what you are seeing.

I'm off highway 55 and state st. between Boise and Eagle. If you are in the area that would be great... I'm thinking I have the valves off as it was running perfect before I decided to put my thumb in it... I'm having a hard time with figuring out TDC on #1 by watching the push rods as I turn the crank, if I can figure that out I can do the rest...If you can get a video that might help us figure it out. Where about in Idaho are you? I am in the Treasure Valley and might be able to come look in person with my scan tools if you are in that general area.

I tend to agree that it is unlikely an injector went out, unless they were damaged/contaminated during the work. If you were careful and clean, that is probably not the problem. Having the valve lash way off could do what you are seeing.

I am out of town for a couple days, but when I get back I can swing by, if you don't get it sorted out by then.I'm off highway 55 and state st. between Boise and Eagle. If you are in the area that would be great... I'm thinking I have the valves off as it was running perfect before I decided to put my thumb in it... I'm having a hard time with figuring out TDC on #1 by watching the push rods as I turn the crank, if I can figure that out I can do the rest...

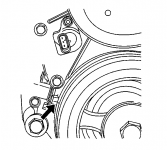

On the LB7 & LLY there is a timing mark for TDC on cylinder #1 (near the cam position sensor). I would be surprised if the LBZ didn't have one too.

I've got all that, just not sure how to tell if I'm out 180, how do I tell if I'm at the top of the compression or the exhaust stroke?? I know it matters in a gas engine because of the distributor or does it matter on a diesel??I am out of town for a couple days, but when I get back I can swing by, if you don't get it sorted out by then.

On the LB7 & LLY there is a timing mark for TDC on cylinder #1 (near the cam position sensor). I would be surprised if the LBZ didn't have one too.

View attachment 106840

The way I do it requires the lash to have been vaguely close to begin with. I simply bring it to TDC, then see which valves are loose, and match it to one of the two sets of valves to adjust.

If you are worried you adjusted them backwards (set the compression stroke valves when it was on the exhaust stroke) you will need to rotate the engine over slowly and observe which valves are opening on cylinder #1. Should go intake → neither → exhaust → intake and repeat. When the intake valve closes, keep rotating the engine until you reach TDC, and that should be the top of the compression stroke.

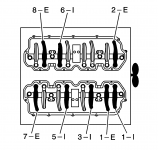

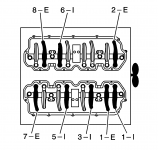

Then go ahead and adjust the marked valves:

If you are worried you adjusted them backwards (set the compression stroke valves when it was on the exhaust stroke) you will need to rotate the engine over slowly and observe which valves are opening on cylinder #1. Should go intake → neither → exhaust → intake and repeat. When the intake valve closes, keep rotating the engine until you reach TDC, and that should be the top of the compression stroke.

Then go ahead and adjust the marked valves:

When I did the LLY, it's pretty easy one you determine TDC #1, but I did verify and check the lash 2X just to ensure that I had them all correct. If you are off 180, I would be worried that a bent push rod could happen.

Blue smoke would be oil. How much have you ran it since the re assembly? Oil in the piston bores, exhaust manifolds, and turbo can take a bit to get cleared. If you did not send the heads in to be checked, did you at least use a long straight edge and 1200 grit or better to lightly remove any gasket material on the head and the block?

White smoke only would indicate lack of compression for firing. This is what I had when I bent the rod in my engine. Smell the exhaust to see if you can detect un burnt fuel (it took me a couple of tries). You may need to use a shop rag over the exhaust to capture enough un burnt fuel to get a good smell of it.

Blue smoke would be oil. How much have you ran it since the re assembly? Oil in the piston bores, exhaust manifolds, and turbo can take a bit to get cleared. If you did not send the heads in to be checked, did you at least use a long straight edge and 1200 grit or better to lightly remove any gasket material on the head and the block?

White smoke only would indicate lack of compression for firing. This is what I had when I bent the rod in my engine. Smell the exhaust to see if you can detect un burnt fuel (it took me a couple of tries). You may need to use a shop rag over the exhaust to capture enough un burnt fuel to get a good smell of it.

I'm off highway 55 and state st. between Boise and Eagle. If you are in the area that would be great... I'm thinking I have the valves off as it was running perfect before I decided to put my thumb in it... I'm having a hard time with figuring out TDC on #1 by watching the push rods as I turn the crank, if I can figure that out I can do the rest...

Contact Pat at Big Twin Diesel in Meridian. He has a great Dmax mechanic and is the only shop that works on my rig...

Big Twin Diesel

670 E King St,

Meridian, ID 83642

(208) 888-7297

Contact Pat at Big Twin Diesel in Meridian. He has a great Dmax mechanic and is the only shop that works on my rig...

Big Twin Diesel

670 E King St,

Meridian, ID 83642

(208) 888-7297

Thanks for all the help Rob. I'm going to work on it here in a bit, and thanks for the diagram I'll use that. So after I gauge the blacked out valves roll it 360 to the others or 180?The way I do it requires the lash to have been vaguely close to begin with. I simply bring it to TDC, then see which valves are loose, and match it to one of the two sets of valves to adjust.

If you are worried you adjusted them backwards (set the compression stroke valves when it was on the exhaust stroke) you will need to rotate the engine over slowly and observe which valves are opening on cylinder #1. Should go intake → neither → exhaust → intake and repeat. When the intake valve closes, keep rotating the engine until you reach TDC, and that should be the top of the compression stroke.

Then go ahead and adjust the marked valves:

View attachment 106841

I let it run for maybe 30 seconds, revved it a couple times not way high just to listen to it that's when it smoked but only when I gave it some rpms, really ran rough. I did run a straight edge and looked for daylight, they were nice and flat, I did clean all the crap real good on both the head and the block before I put the gaskets on. I used Track Tech class C from Prosource Diesel along with the ARP head bolts. I'm leaning towards having set it 180 out and bent a rod or two. I'll find out this morning. I only have the psngr side torn down, I'll start with that side before i get into the drivers side which a PITA...When I did the LLY, it's pretty easy one you determine TDC #1, but I did verify and check the lash 2X just to ensure that I had them all correct. If you are off 180, I would be worried that a bent push rod could happen.

Blue smoke would be oil. How much have you ran it since the re assembly? Oil in the piston bores, exhaust manifolds, and turbo can take a bit to get cleared. If you did not send the heads in to be checked, did you at least use a long straight edge and 1200 grit or better to lightly remove any gasket material on the head and the block?

White smoke only would indicate lack of compression for firing. This is what I had when I bent the rod in my engine. Smell the exhaust to see if you can detect un burnt fuel (it took me a couple of tries). You may need to use a shop rag over the exhaust to capture enough un burnt fuel to get a good smell of it.

I would think there are 2 ways of doing this. One is to find TDC at the compression stroke and do the valves that are closed then roll it which is what I did but you can be off 180. The other would be to adjust them individually when each valve is closed I guess at that point it would not matter what stroke it's on just takes a bit longer cause you have to roll the crank for each valve...Does the motor need to be at TDC to adjust valves? Wouldn’t watching the intake and exhaust valve open then close and stop moving be sufficient

did you replace just the bent rod or all of them??I let it run for maybe 30 seconds, revved it a couple times not way high just to listen to it that's when it smoked but only when I gave it some rpms, really ran rough. I did run a straight edge and looked for daylight, they were nice and flat, I did clean all the crap real good on both the head and the block before I put the gaskets on. I used Track Tech class C from Prosource Diesel along with the ARP head bolts. I'm leaning towards having set it 180 out and bent a rod or two. I'll find out this morning. I only have the psngr side torn down, I'll start with that side before i get into the drivers side which a PITA...