Just repowered a 2007 LBZ, customer brought me a supposedly running short block that had been hit, he put new covers on and front and rear. I put the rest together with new injectors, turbo, cp3 etc.

Truck drove in. New engine won't start, It catches then nothing. I have code P0341. Tried know cam senor-not change. Checked wheels as best as possible for damage, same with crank, can't see anything. Scoped crank, good pattern.

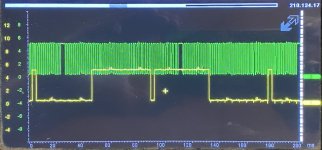

Cam has a weird pattern. I get one small square wave, then bigger then bigger. From what I've seen, its suppoed to be equal sqaure waves. Thanks

Truck drove in. New engine won't start, It catches then nothing. I have code P0341. Tried know cam senor-not change. Checked wheels as best as possible for damage, same with crank, can't see anything. Scoped crank, good pattern.

Cam has a weird pattern. I get one small square wave, then bigger then bigger. From what I've seen, its suppoed to be equal sqaure waves. Thanks